Troubleshooting Common Issues With Rotary Screw Compressors

Rotary screw compressors are essential components in many industrial applications, offering reliable and efficient performance. However, like all mechanical equipment, they are prone to specific issues that can disrupt operations. Identifying and resolving these problems quickly is fundamental to maintaining productivity and extending the lifespan of the machinery. In this article, we will delve into the common issues associated with rotary screw compressors. Keep reading for expert insights and practical solutions.

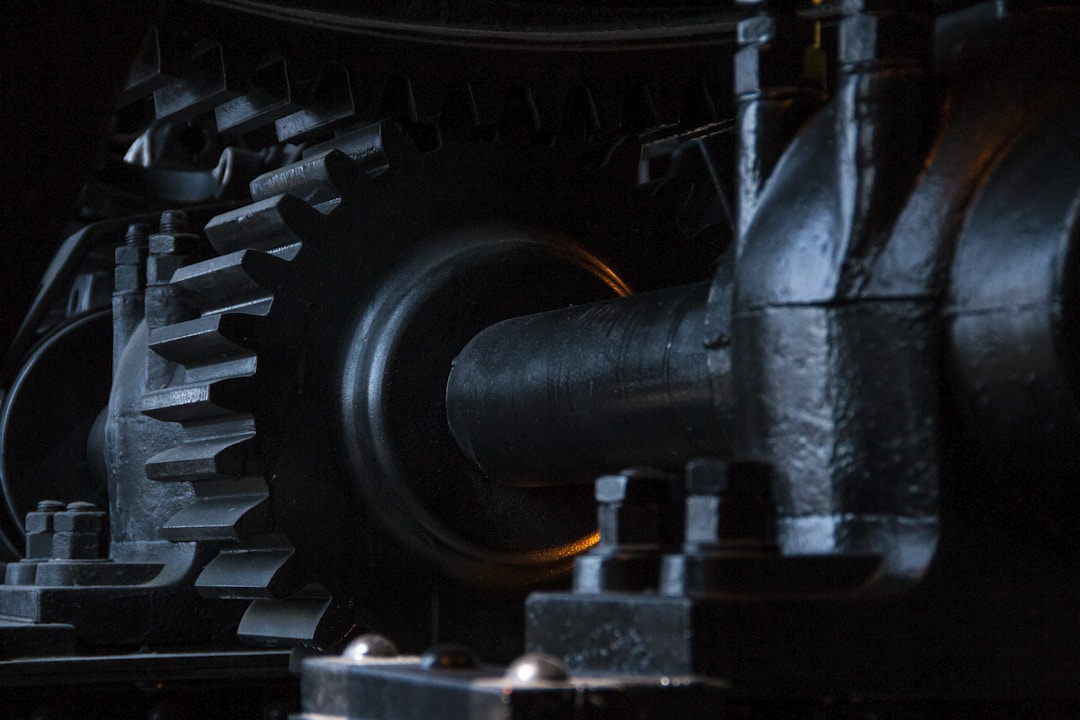

Understanding the Basics of Rotary Screw Compressor Functionality

At the heart of rotary screw compressors lies a pair of helical screws, which are the main components responsible for compressing the air or gas. As these screws rotate, the volume between them and the casing decreases, which compresses the air or gas inside. This process is continuous, providing a steady flow of compressed air essential for many industrial processes.

The efficiency of a rotary screw compressor highly depends on the alignment and synchronization of the screws. Over time, wear and tear can impact these parameters, leading to reduced performance. Understanding the basic mechanics of these machines is crucial for effective troubleshooting and maintenance.

Another key aspect of functionality is the lubrication system, which ensures that the moving parts operate smoothly and without excess friction. Proper maintenance of the oil filter and separator is vital to prevent potential issues such as oil carryover or increased wear on the components.

Temperature control is also essential, as excessive heat can damage the compressor parts and degrade the quality of the oil. Cooling systems are there to dissipate heat efficiently, ensuring the longevity of the equipment. An adequate understanding of these fundamental principles is critical when diagnosing problems with your compressor.

Identifying Common Symptoms of Rotary Screw Compressor Failures

One of the first signs of a rotary screw compressor failure is an unexpected change in pressure. A pressure drop indicates potential leaks or a fault within the compression stage. Conversely, excessive pressure may point to a blockage or malfunctioning pressure relief component.

Unusual noises such as grinding, knocking, or hissing can signal internal mechanical issues or escaping gas. These auditory cues should not be ignored, as they often precede more severe complications. Paying close attention to changes in sound during operation is a simple yet effective diagnostic tool.

Excessive heat generation or high temperatures beyond normal operating ranges is another symptom to watch for. Overheating may result in a compressor shutdown as a protective measure to prevent damage. This symptom could be related to the cooling system, lubrication, overuse, and insufficient downtime.

Step-by-Step Guide To Diagnosing Operational Issues

Begin troubleshooting operational issues by conducting a thorough visual inspection of your rotary screw compressor. Look for any signs of oil leaks, damaged components, or unusual wear that could be contributing to performance issues. Checking for loose fittings and ensuring all connections are secure can resolve some straightforward problems.

Monitoring performance metrics such as pressure, temperature, and electricity usage can provide valuable clues about the compressor’s state. Sudden changes in these parameters often point to specific components or processes that require attention. It’s important to compare current performance to the manufacturer’s specifications to spot discrepancies.

Auditory diagnostics can be just as revealing, as different sounds can be symptomatic of various issues. For example, a continuous hissing might indicate a leak, while a metal-on-metal sound could signal bearings in need of replacement. Always prioritize safety and shut down the compressor before attempting to locate the source of any abnormal noise.

In cases of overheating or thermal overload, examine the cooling system and airflow around the compressor. Ensure the radiator or air coolers are not obstructed and that fans are functioning correctly. If the problem persists, it might be a signal for a deeper investigation or a call to a professional technician.

Understanding the functionality of your rotary screw compressor and being vigilant in maintenance practices can greatly reduce the likelihood of emergencies. By following this comprehensive guide, you’ll be well-equipped to handle most issues that come your way and keep your compressor running smoothly for years to come.

Troubleshooting common issues with rotary screw compressors is essential for maintaining productivity in industrial settings. As you delve into the complexities of compressor functionality and diagnostics, consider these insights:

How to Choose the Right Wine for Different Occasions: Just as selecting the right wine enhances various occasions, understanding the basics of rotary screw compressor functionality is crucial for effective troubleshooting. Familiarize yourself with the mechanics of helical screws, lubrication systems, and temperature control to diagnose and resolve operational issues efficiently.

Why Preschool Teachers Need to be CPR Certified: Prioritize safety during troubleshooting by identifying common symptoms of rotary screw compressor failures. Unexpected changes in pressure, unusual noises, and excessive heat generation are warning signs that require immediate attention to prevent further damage.

How to Plan the Perfect Rave: Approach troubleshooting with a step-by-step guide, beginning with a visual inspection of the compressor for oil leaks, damaged components, or wear. Monitor performance metrics such as pressure and temperature to pinpoint specific issues, and conduct auditory diagnostics to identify abnormal sounds indicative of mechanical problems.

Learning to Love Again: How to Reconnect with a Partner Following Infidelity: Ensure the longevity of your compressor by understanding its functionality and adhering to proper maintenance practices. Regular visual inspections, performance monitoring, and prompt attention to abnormalities will prolong the lifespan of your equipment and minimize downtime.

What Kind of Windows Do Bathrooms Need: Consider the importance of airflow and cooling systems in preventing overheating and thermal overload. Keep compressor radiators and air coolers unobstructed to facilitate efficient heat dissipation and airflow. If issues persist, seek professional assistance to address underlying problems and ensure optimal compressor performance.

By integrating these insights into your troubleshooting process, you’ll be well-equipped to identify and resolve common issues with rotary screw compressors, maintaining productivity and minimizing disruptions in industrial operations.